About Us

WELCOME TO

Cradotex Technology Sdn. Bhd.

Cradotex Group was established and incorporated in Malaysia in 1981 to its present capacity as an ISO 9001:2015 and ISO 45001:2018 Certified Integrated Fibreglass Reinforced Plastic Manufacturing Centre. We gained entry into the Composite Fabrication Association in 1995 which gives updates on FRP Advanced Technology.

Cradotex Group are recognized as the leader in FRP/GRP Manufacturing Industries through successful projects delivered in the past. In the meantime, we are also proud to be one of the biggest FRP/GRP Engineer and Quality Manufacturer in Malaysia.

Do you know that Cradotex is…

- The leader in FRP / GRP Manufacturing Industries through the successful projects delivered in the past

- One of the biggest FRP/ GRP Engineer and Quality Manufacturer in Malaysia

- Fibreglass product technology is based on innovative research and a thorough knowledge of process control and application technology

Core Business

Fiber Glass, GRP and FRP Design Capabilities, Fabrication and Services.

Build-up Area: Land area = 24,155 m2

Production area = 5134 m2

Office & Store area = 1024 m2

Cradotex Group understand the needs of the industry and will continuously work towards meeting those needs.

- Design capabilities – Design code BS4994, BS EN 13121, ASME RTP – 1 Standard

- A certified ISO9001:2015 Quality Management System and ISO 45001: 2018 occupational health and safety Malaysia company

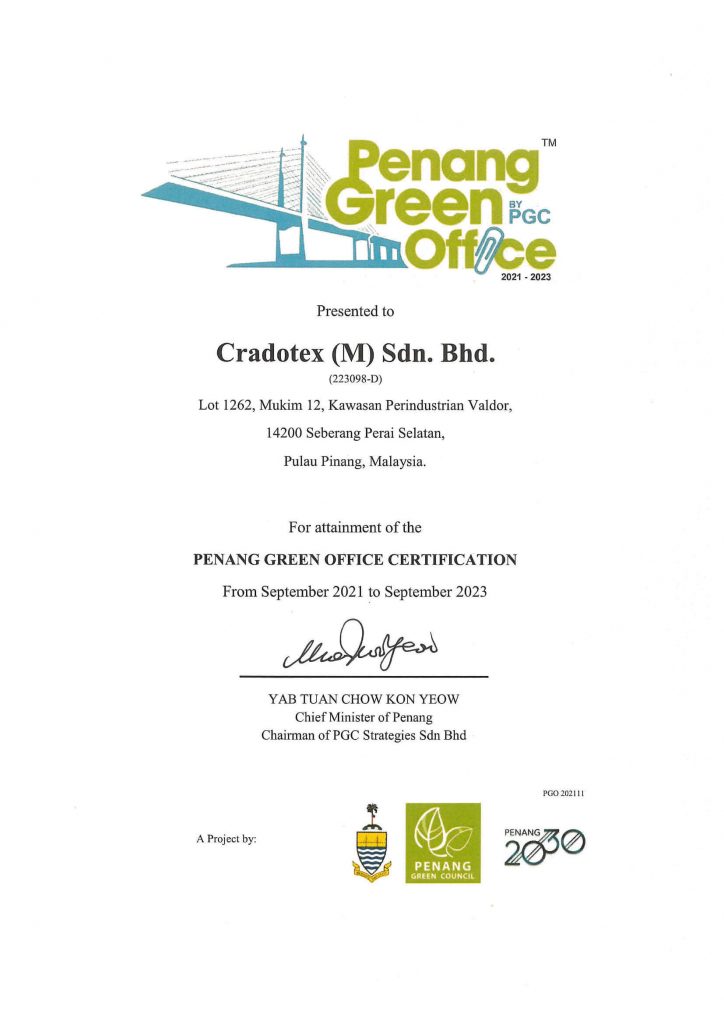

- A Penang Green Office certified company

Our Visions

- Quality Products and Services of Worldwide Standards and Recognition

- Product Excellence and Customer’s Satisfaction is our Manufacturing Objectives

Quality Objectives

- To grow and become a major player in the field of Fiberglass Reinforced Plastic Products with yearly sales growth of 30%

- To achieve 100% on time deliveries of products

- To achieve customer satisfaction level up to 80%

Quality Policy

- Provide products and services that meet the needs of our customers and exceed their expectations

- Satisfy our customer with deliveries on time and provide optimal solutions

- Continually improve the Quality Management System to ensure the quality at every stage as essential to ensure product conformance

Industries Served

- Water and Waste Treatment Plants

- Chemical and Petroleum Processing Industry

- Agricultural Industry

- Boating Industry

- Food and Beverages Industry

- Pulp and Paper Industry

- Power Industry

- Automotive Industry

- Electronics Semiconductor Industry

- Solar Cell Industry

- Rare Earth Processing Plant

- Tin Processing Plant

- Metal Treating and Electro Plating

- Mining Industry

Project Undertaken

Singapore Client (Through Main Contractors)

- Vietnam Oil & Gas Corporation (Petrovietnam)

- Webel SL Energy System Ltd.

- Sun Power Malaysia Manufacturing Sdn. Bhd.

- FCI Microconnection

- REC Cells Pte. Ltd.

- IM Flash Singapore

- Showa Denko

- ST Microelectronics Pte. Ltd.

- Soitec Singapore Pte. Ltd.

- Seagate International (Johor) Sdn. Bhd.

- Bedok Newater

- Schering- Plough Ltd.

- Hyflux Hydrochem (S) Pte. Ltd.

- Kranji Sewage Treatment Water Plant.

Overseas Client

- SV Plastics

- Khai Hoan Joints Stock Company

- Hydrogreen Technology Sdn. Bhd.

Local Client

- Vinyl Chloride (Malaysia) Sdn. Bhd.

- Infineon Technologies (Malaysia) Sdn. Bhd.

- Malaysia Smelting Corporation Berhad

- Advanced Micro Devices Sdn. Bhd.

- Lynas Malaysia Sdn. Bhd.

- Hewlett – Packard (Malaysia) Sdn. Bhd.

- Intel Technology (M) Sdn. Bhd.

- First Solar, Inc.

- Agilent Technologies (Malaysia) Sdn. Bhd.

- Ansell (Kedah) Sdn. Bhd.

- Top Glove Sdn. Bhd.

- Konica Minolta Glass Tech (M) Sdn. Bhd.

- Q-Cells Malaysia Sdn. Bhd.

- Lemtronics Sdn. Bhd.

- LRC Hospital Products (M) Sdn. Bhd.

- Fairchild Semiconductor (Malaysia) Sdn. Bhd

- National Semiconductor Corporation Technology Sdn. Bhd.

- Renesas Semiconductor Sdn. Bhd.

- B Braun Medical Industries Sdn. Bhd.

- Datuk Kramat Smelting Sdn. Bhd.

- Reclaimtek (M) Sdn. Bhd.

- CMKS Malaysia Sdn. Bhd.

- Tong Heer Fasteners Co. Sdn. Bhd.

- Osram Opto Semiconductor (M) Sdn. Bhd.

- Polyglass Fibre Manufacturing Sdn. Bhd.

- Federal Fertilizer Co. Sdn. Bhd.

- Amphenol TCS (M) Sdn. Bhd.

- Ming Engineering Plastic Sdn. Bhd.

- TS Solartech Sdn. Bhd.

Technical Information

Able to cater for a wide variety of resins with state of the art filament winding machines and precision molds for hand layup work

Tank Construction Design

The most important feature of a fiberglass tank is the corrosion resistance of the tank. Our corrosion barrier laminate is made up of the Inner Surface and Interior Layer combined. Our FRP tank is built using a mold to ensure a resin rich smooth internal barrier to create better corrosion resistance.

Product Type Specialize

- Square Tank Products

- Custom Designed Products

- FRP Piping

- Round Tank Products

- Fume Scrubber System

- Underground Effluent Tanks

- Industrial Effluent Treatment System

- Treatment Works

- Gutters

- Anti-Corrosion Lining

- Panels and Insulators

- Boats

- Cleaning, Repairs and Inspection Services of FRP Products

- Silos